Decoding Piping & Instrumentation Diagrams: A Comprehensive Guide to P&ID Symbols

Imagine a visual language that speaks volumes about complex industrial processes – a roadmap for engineers, operators, and technicians alike. That's the power of Piping and Instrumentation Diagrams, commonly known as P&IDs. These intricate drawings, brimming with specialized symbols, represent the backbone of process industries, from oil refineries to pharmaceutical plants. Understanding these symbolic representations is essential for anyone involved in designing, operating, or maintaining process systems.

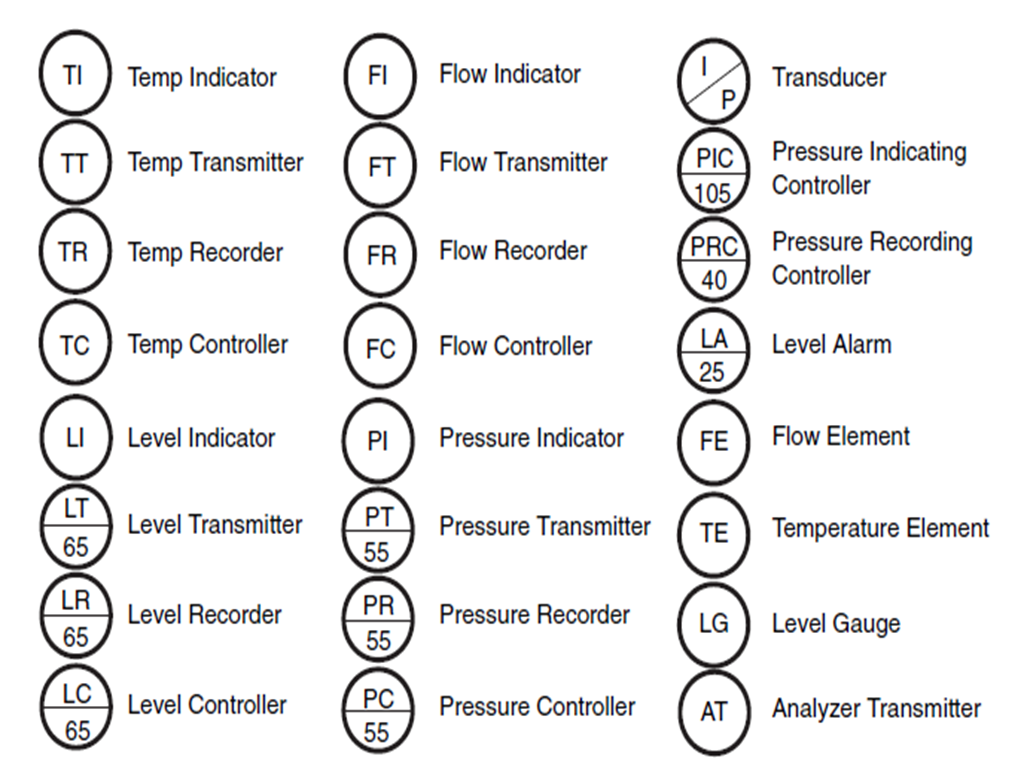

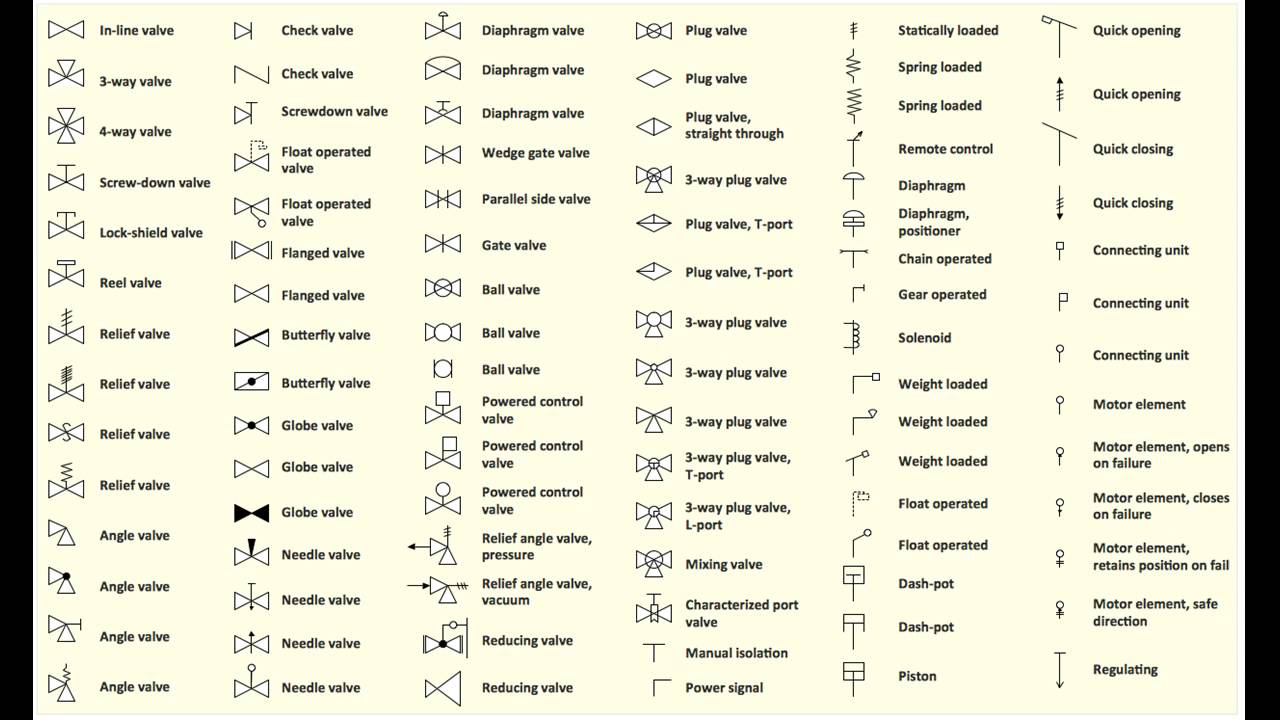

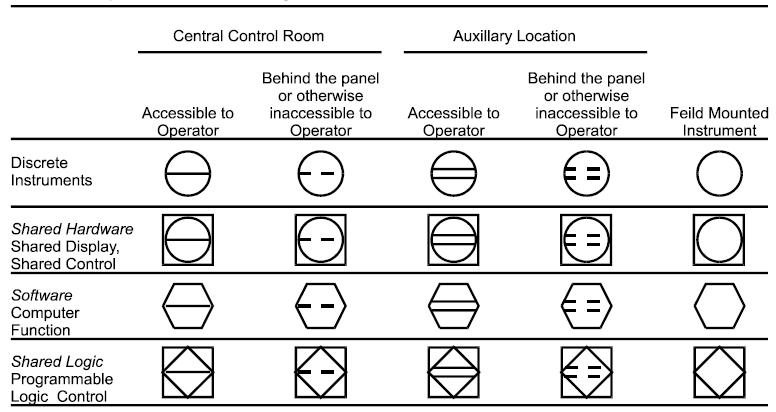

A P&ID symbol library, essentially a comprehensive key to this visual language, offers a standardized vocabulary for describing process equipment, piping, instrumentation, and control systems. Think of it as the Rosetta Stone for process engineering, unlocking a wealth of information about how fluids and materials flow, are controlled, and interact within a complex system. Whether you're a seasoned engineer or a budding technician, mastering these symbols opens doors to a deeper understanding of process design and operation.

Delving into the historical context of P&ID symbols reveals their evolution alongside the growth of complex industrial processes. Early diagrams were often rudimentary, evolving from simple flow sketches to standardized representations driven by the need for clear communication and safety. The importance of a universal language for depicting process flow became evident, leading to the development of standardized symbol libraries by organizations like ISA (International Society of Automation). This standardization has significantly reduced ambiguity and improved communication among professionals across the globe.

Navigating the world of P&ID symbols can be challenging. One of the main issues is the potential for misinterpretation if the symbols are not clearly defined or understood by all parties involved. Inconsistency in symbol usage can lead to errors in design, operation, and maintenance, potentially resulting in safety hazards or inefficiencies. Therefore, adhering to standardized symbol libraries and ensuring thorough training for all personnel involved in using P&IDs is crucial.

Fortunately, numerous resources offer extensive lists of P&ID symbols, providing detailed explanations and examples. These resources, often available online or in specialized handbooks, serve as invaluable tools for both learning and practical application. Understanding the nuances of each symbol, from valves and pumps to instruments and control systems, allows for accurate interpretation of the diagram and effective communication within project teams.

Benefits of using a standardized list of P&ID symbols include improved communication, reduced design errors, and enhanced safety. For example, a universally recognized symbol for a check valve eliminates ambiguity, ensuring that everyone involved understands its function within the system. This clear communication reduces the risk of misinterpretation during design, construction, and operation.

Benefits of using a standardized list of P&ID symbols include improved communication, reduced design errors, and enhanced safety. For example, a universally recognized symbol for a check valve eliminates ambiguity, ensuring that everyone involved understands its function within the system. This clear communication reduces the risk of misinterpretation during design, construction, and operation.

Benefits of using a standardized list of P&ID symbols include improved communication, reduced design errors, and enhanced safety. For example, a universally recognized symbol for a check valve eliminates ambiguity, ensuring that everyone involved understands its function within the system. This clear communication reduces the risk of misinterpretation during design, construction, and operation.

Frequently Asked Questions about P&ID Symbols:

1. What is a P&ID? - A P&ID is a detailed diagram that illustrates the piping, equipment, and instrumentation of a process system.

2. Where can I find a P&ID symbol list? - Many resources, including ISA standards and online databases, provide comprehensive lists of P&ID symbols.

3. Why are P&ID symbols important? - Standardized symbols ensure clear communication and minimize errors in design and operation.

4. What are some common P&ID symbols? - Common symbols include those for valves, pumps, instruments, and piping.

5. How can I learn to interpret P&IDs? - Numerous training resources and online tutorials are available to help individuals understand P&IDs.

6. Who uses P&IDs? - Engineers, operators, technicians, and other professionals involved in process industries use P&IDs.

7. How do P&ID symbols contribute to safety? - Clear and accurate representation of process systems through standardized symbols enhances safety by reducing the risk of misinterpretation.

8. What is the role of ISA in P&ID standardization? - ISA develops and maintains standards for instrumentation and automation, including P&ID symbols, promoting consistency and best practices.

In conclusion, the seemingly intricate world of P&ID symbols is fundamental to the successful design, operation, and maintenance of process systems. Understanding the language of these symbols empowers professionals to effectively communicate complex information, minimizing errors and enhancing safety. From preventing costly misinterpretations to facilitating seamless collaboration, mastering this symbolic lexicon unlocks the full potential of process engineering and contributes to a safer and more efficient industrial landscape. By embracing the power of standardized P&ID symbols, we can elevate communication, optimize processes, and pave the way for a more interconnected and efficient industrial future. Start exploring the world of P&ID symbols today and unlock a new level of understanding in process engineering.

Unlocking your fords wheel bolt pattern the ultimate guide

The silent symphony of torque decoding wheel fastener tightening

Penn state fall semester start date