Keep Your Inboard Motor Alive: The Impeller Saga

Ever feel like your inboard motor is gasping for breath? Overheating maybe? Before you start picturing catastrophic engine failure and a hefty repair bill, consider a smaller, often overlooked component: the impeller. This rubber wonder is the heart of your engine's cooling system, and understanding its maintenance can save you a whole lot of trouble (and money) down the line.

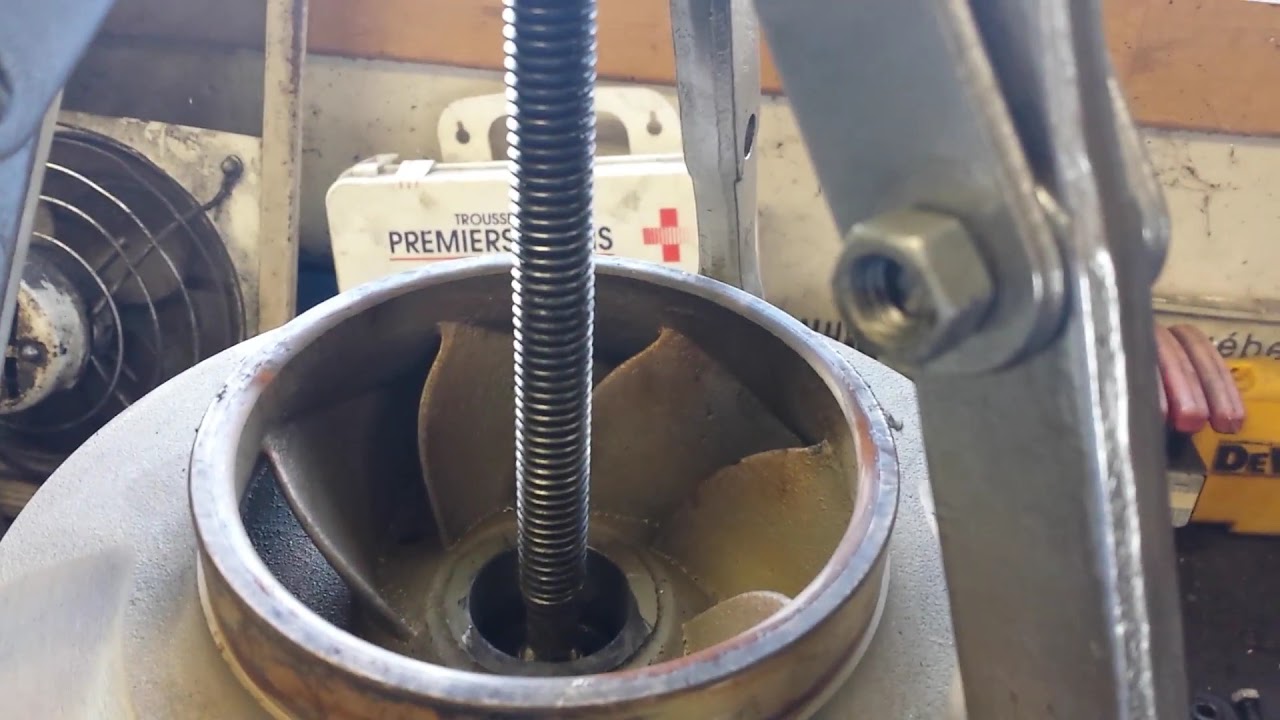

The impeller, a flexible, finned wheel, resides within the water pump. Its job is to draw cooling water from the surrounding source and circulate it through the engine block, preventing overheating. It's a constant cycle of intake and expulsion, a watery heartbeat keeping your engine alive. But like any hardworking part, the impeller is subject to wear and tear.

An impeller replacement isn't a lifetime commitment. Depending on usage, material, and water conditions, these rubber warriors usually need replacing every two to three years. Neglecting this simple maintenance can lead to serious consequences, from decreased engine performance and overheating to complete engine failure. Think of it like changing the oil in your car – a small, preventative measure that avoids major headaches later.

In the early days of inboard motors, cooling systems were simpler, sometimes relying on direct water flow. The introduction of the impeller revolutionized cooling efficiency, allowing for better temperature regulation and higher engine performance. Replacing the impeller used to be a more involved process, but modern designs and readily available parts have made it a relatively straightforward task for the average boat owner.

The main issue related to impellers is their vulnerability to wear and tear. Debris in the water, running the engine dry, even age itself, can contribute to impeller degradation. Recognizing the signs of a failing impeller is critical. Overheating is the most obvious symptom, but also look out for reduced water flow from the tell-tale, strange noises from the water pump, and steam or smoke from the engine compartment. Catching these early warnings can prevent catastrophic damage.

Impeller replacement on an inboard motor, simply put, means swapping out the old, worn impeller with a fresh, new one. It’s like giving your engine's cooling system a refreshing gulp of water after a marathon. For example, imagine your garden hose with a kink in it - reduced water flow. A new impeller is like straightening out that hose, restoring optimal flow.

Maintaining a functional impeller comes with numerous benefits. First, it prevents overheating, which can lead to severe engine damage. Second, a healthy impeller ensures optimal engine performance, allowing you to enjoy smooth sailing. And third, regular impeller changes extend the overall lifespan of your inboard motor, saving you from costly repairs in the long run.

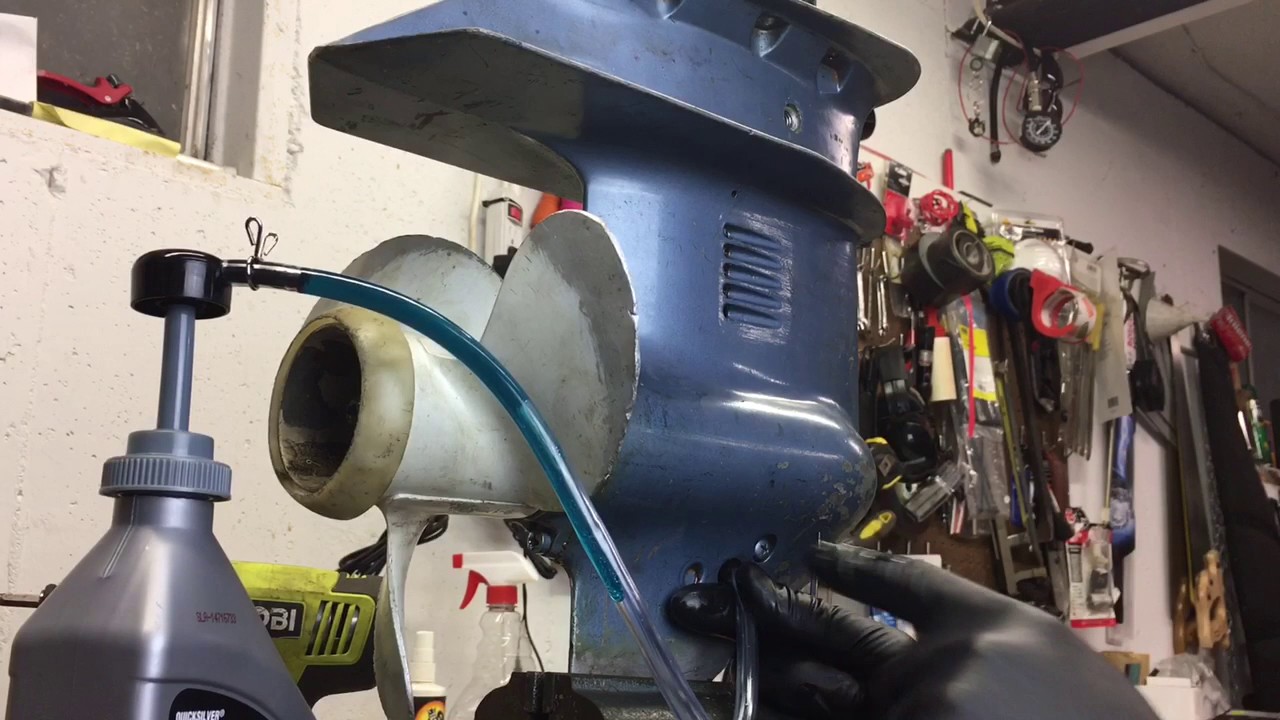

Creating an action plan for impeller replacement involves a few key steps: Purchase the correct impeller for your engine model, gather the necessary tools (typically a screwdriver and pliers), locate the water pump on your inboard motor, and follow the specific instructions for your engine to remove the old impeller and install the new one. Remember to lubricate the new impeller before installation for a smooth fit. Successful examples abound online, with countless boat owners sharing their impeller replacement journeys.

Advantages and Disadvantages of Regular Impeller Changes

| Advantages | Disadvantages |

|---|---|

| Prevents costly engine damage due to overheating | Requires some time and effort |

| Ensures optimal engine performance | Small cost for the new impeller |

| Extends engine lifespan |

Best Practices for Impeller Replacement include: Inspecting the housing for debris or damage, using a lubricant for installation, double-checking the impeller's orientation, using the correct tools, and testing the cooling system after replacement. Real-world examples could include situations where boaters averted potential engine failure by proactively changing their impellers or instances where neglecting this simple maintenance led to costly repairs.

Frequently Asked Questions: How often should I replace my impeller? What are the signs of a failing impeller? Where can I buy a replacement impeller? What tools do I need? Can I do it myself? What type of lubricant should I use? How do I know if I installed it correctly? How do I test the cooling system after replacing the impeller?

Tips and tricks for impeller replacement: Take photos before disassembly for easy reassembly. Use a small mirror to inspect hard-to-see areas. Mark the impeller housing to ensure proper alignment. Keep spare impellers on board for emergencies.

In conclusion, the seemingly small impeller plays a vital role in the health and longevity of your inboard motor. Regular impeller changes, a relatively simple and inexpensive preventative measure, can save you from costly repairs and ensure optimal engine performance. Understanding the importance of this little rubber warrior empowers you to take control of your boat's maintenance and enjoy smooth sailing for years to come. Don't wait for disaster to strike – prioritize impeller maintenance and keep your engine purring happily. Invest in the health of your inboard motor, and it will reward you with countless hours of trouble-free boating. Now, go out there and conquer the waves!

The mccarthy era unravelled

Benjamin moore cottage red exterior a timeless classic

Calhoun county property tax payments a comprehensive guide