Keep Your Mercury Marine Engine Cool A Guide to Water Pump Impellers

Is your Mercury Marine engine overheating? A failing water pump impeller might be the culprit. This crucial component plays a vital role in keeping your outboard or sterndrive engine running smoothly. Understanding its function and maintenance is essential for any boat owner.

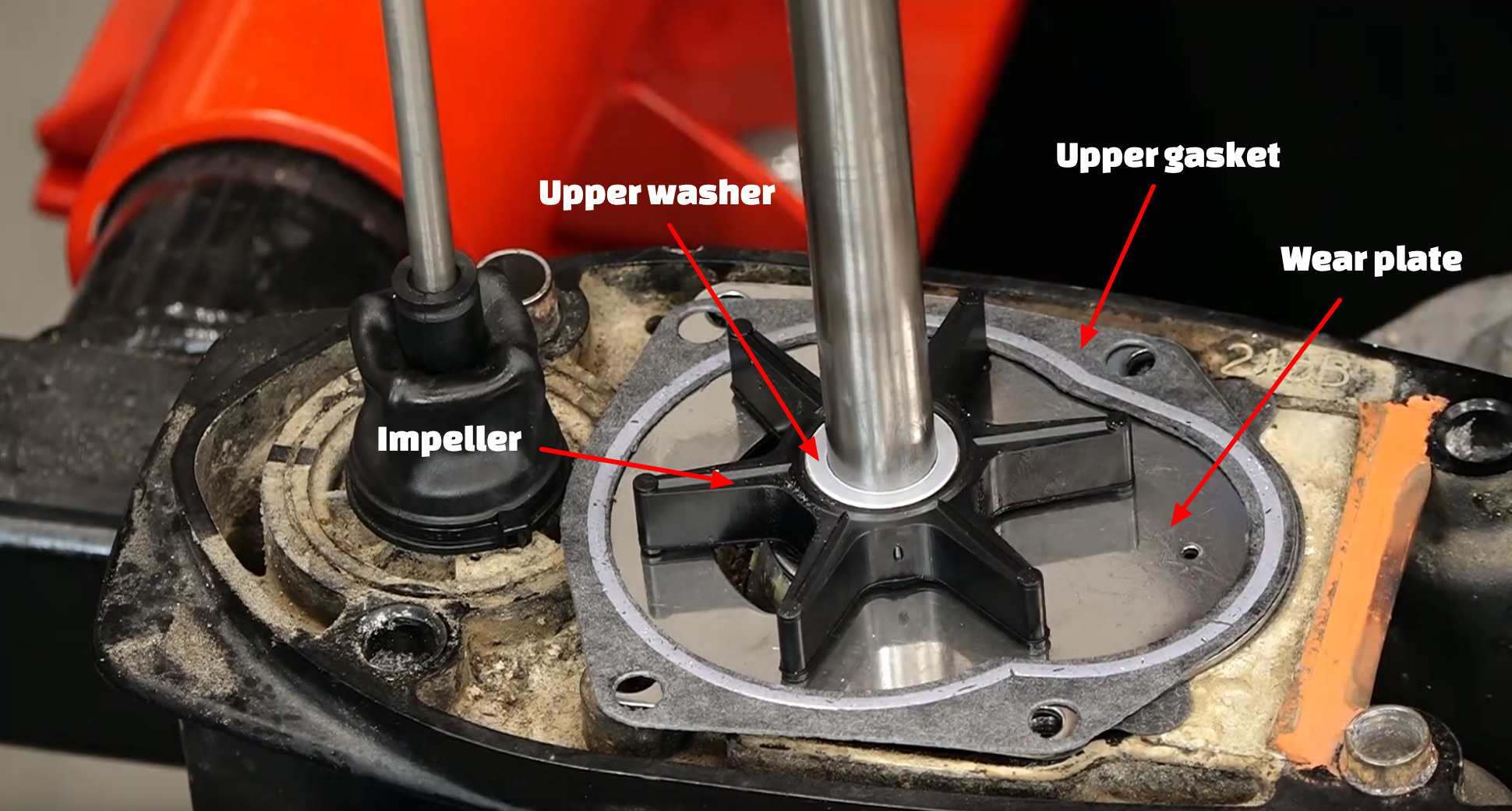

The Mercury Marine water pump impeller is a small, rubber component located within the water pump housing. Its purpose is to draw cooling water from the surrounding body of water and circulate it through the engine block. This process dissipates heat generated by the engine, preventing overheating and potential damage.

Neglecting your Mercury outboard or sterndrive water pump impeller can lead to significant problems. An impeller in poor condition can restrict water flow, causing the engine to overheat and potentially seize. Regular inspection and replacement of the impeller are crucial preventative measures that can save you from costly repairs down the road. This guide will explore everything you need to know about your Mercury Marine water pump impeller, from its function and importance to maintenance and troubleshooting.

The history of the marine water pump impeller is tied to the development of internal combustion engines for boats. As engines became more powerful, the need for efficient cooling systems became paramount. The impeller, with its simple yet effective design, became the standard for circulating cooling water in outboard and sterndrive engines. Early impellers were often made of less durable materials, requiring more frequent replacements. Modern Mercury Marine impellers are designed with advanced materials for improved longevity and performance.

The importance of a properly functioning Mercury water pump impeller cannot be overstated. It is the heart of the cooling system, responsible for maintaining optimal engine temperature. Without a consistent flow of cooling water provided by the impeller, your engine is at risk of overheating, leading to potential damage to internal components, including the cylinder head, pistons, and even the engine block itself. Regular maintenance, including inspecting and replacing the water pump impeller as needed, is crucial for preventing these costly repairs and ensuring the longevity of your Mercury Marine engine.

One of the main issues related to Mercury Marine water pump impellers is damage due to running the engine dry. Even a short period of dry running can cause the impeller blades to warp, crack, or break, leading to reduced water flow and potential overheating. Another common issue is debris clogging the impeller. Sand, small stones, and other debris can get sucked into the water pump, damaging the impeller and restricting water flow. Regular impeller inspections and cleaning can help prevent these problems.

Benefits of a well-maintained Mercury Marine water pump impeller include: 1. Preventing overheating: A functioning impeller ensures adequate water circulation, keeping the engine at optimal temperature. 2. Extending engine life: By preventing overheating, a healthy impeller contributes to the longevity of the engine. 3. Enhanced boating experience: A reliable cooling system provides peace of mind and allows for uninterrupted enjoyment on the water.

Creating an action plan for maintaining your impeller is straightforward: 1. Inspect the impeller visually at least once a season. 2. Replace the impeller every 1-2 years, or more frequently if you operate in shallow or debris-filled waters. 3. Keep spare impellers on board for emergencies.

Advantages and Disadvantages of Mercury Marine Water Pump Impellers

| Advantages | Disadvantages |

|---|---|

| Essential for engine cooling | Subject to wear and tear |

| Relatively inexpensive to replace | Can be damaged by debris |

| Easy to inspect and replace | Requires regular maintenance |

Five best practices for impeller maintenance include: 1. Use a genuine Mercury Marine impeller for optimal performance and durability. 2. Lubricate the impeller with glycerin or soapy water during installation. 3. Inspect the impeller housing for damage or debris. 4. Flush the cooling system after each use, especially in saltwater environments. 5. Store spare impellers in a cool, dry place.

Frequently asked questions include: 1. How often should I replace my impeller? (Every 1-2 years) 2. What are the signs of a failing impeller? (Overheating, reduced water flow) 3. Can I replace the impeller myself? (Yes, with basic tools) 4. What type of impeller do I need for my engine? (Consult your owner's manual) 5. What causes impeller failure? (Dry running, debris, age) 6. How do I inspect my impeller? (Remove the water pump housing and visually examine the impeller) 7. Can I use an aftermarket impeller? (While possible, genuine Mercury Marine impellers are recommended) 8. Where can I purchase a Mercury Marine impeller? (Authorized Mercury Marine dealers)

Tips and tricks include checking the impeller for damage after hitting debris and carrying a spare impeller kit. Understanding the importance of regular impeller maintenance can save you from costly repairs and ensure your Mercury Marine engine performs reliably for years to come.

In conclusion, the Mercury Marine water pump impeller is a critical component for any boat owner. Understanding its function, recognizing signs of wear, and following a regular maintenance schedule are essential for ensuring the health and longevity of your outboard or sterndrive engine. By investing a small amount of time and effort in maintaining your impeller, you can avoid costly repairs and enjoy countless hours of trouble-free boating. Remember to always use genuine Mercury Marine parts for optimal performance and reliability. Don't let a failing impeller ruin your boating experience. Take the necessary steps to keep your engine cool and protected, ensuring years of enjoyable time on the water. Check your impeller today and enjoy peace of mind knowing your engine is protected.

Why is my ac so loud troubleshooting noisy air conditioners

Unlocking the subtle sophistication of grey matching hues

Decoding sherwin williams paint costs