Mastering Metric Bolt Tightening: Your Guide to Torque Specs

Ever stripped a bolt or had a part fail because it wasn't tightened correctly? It's a frustrating experience, and one that can easily be avoided with the proper knowledge of metric bolt torque specifications. Understanding these tightening guidelines is crucial for everything from assembling furniture to working on complex machinery.

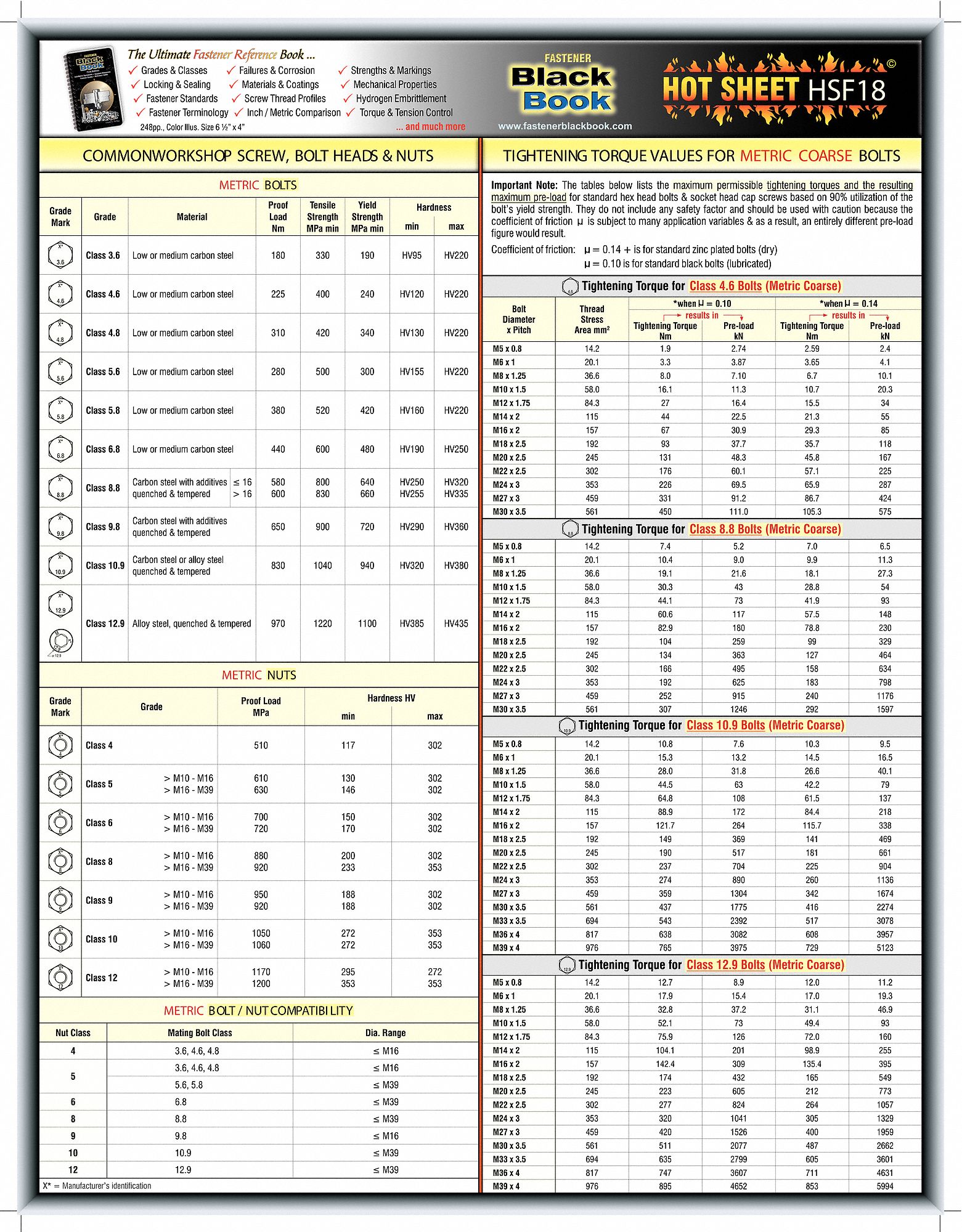

Metric bolt torque charts, often referred to as tightening guidelines or fastener tightening specifications, are essential resources for anyone working with metric fasteners. They provide the recommended tightening force (torque) for specific bolt sizes and grades, ensuring secure and reliable connections. Using the correct torque prevents over-tightening, which can lead to stripped threads or damaged components, and under-tightening, which can result in loose joints and potential failures.

These specifications are derived from extensive engineering testing and analysis, considering factors like material strength, thread pitch, and friction. They are typically presented in tables or charts, making it easy to find the correct torque value for a specific bolt. While these charts are readily available online and in technical manuals, understanding their proper usage is key.

Imagine building a bookshelf and overtightening the screws. The wood could crack, rendering the shelf unusable. Or, picture a loose bolt on a bicycle causing a wheel to come off. These scenarios illustrate the importance of correct bolt tightening, and that's where a metric bolt torque chart comes in handy. It’s your guide to ensuring that every bolt is tightened just right.

The use of standardized torque specifications arose with the increasing complexity of machinery and the need for consistent and reliable assembly. Historically, tightening was often done by "feel," which led to inconsistencies and potential problems. The development of torque wrenches and standardized charts provided a much-needed solution, ensuring that bolts were tightened to the correct specification, regardless of the individual doing the work. This standardization has been vital in industries like automotive, aerospace, and construction.

A metric bolt torque specification is expressed in Newton-meters (Nm). This unit of measurement represents the rotational force applied to the bolt. For example, a torque specification of 20 Nm means you need to apply 20 Newtons of force at a distance of one meter from the bolt's center. Torque wrenches are designed to measure and apply this force accurately.

One benefit of using a metric bolt torque chart is preventing damage to components. Over-tightening can strip threads, deform parts, or even cause fractures. Using the chart ensures you apply the correct torque, safeguarding your equipment. Secondly, proper torque ensures optimal performance. A joint tightened to the correct specification will function as designed, preventing loosening or failure under stress. Finally, consistent torque is key for safety. Imagine a critical component in a car failing due to improper tightening. A torque chart helps mitigate such risks.

To effectively use a metric bolt torque chart, first identify the bolt's size and grade. These are usually marked on the bolt head. Then, consult the chart to find the corresponding torque specification. Use a calibrated torque wrench to apply the specified torque. It’s also important to consider lubrication, as this can affect the final tightening value.

Before tightening any bolt, consult the relevant metric bolt torque chart. Use a calibrated torque wrench. Double-check the bolt size and grade. Ensure the threads are clean and lubricated as specified.

Challenges in using torque specifications can include variations in thread condition, lubricant type, and material properties. Solutions involve using appropriate lubricants, cleaning threads, and consulting manufacturer-specific guidelines.

Advantages and Disadvantages of Using a Torque Chart

| Advantages | Disadvantages |

|---|---|

| Prevents over-tightening and damage | Requires a torque wrench and proper chart |

| Ensures optimal joint performance | Can be time-consuming for large assemblies |

| Improves safety and reliability | Variations in materials and lubricants can affect accuracy |

Real-world examples include tightening cylinder head bolts on an engine, assembling furniture, securing bicycle components, installing plumbing fixtures, and working on industrial machinery.

FAQs: What is a Newton-meter? How do I choose the right torque wrench? What is bolt grade? How does lubrication affect torque? Where can I find metric bolt torque charts? What are the consequences of over-tightening? Under-tightening? What if my bolt size isn't on the chart?

Tips and tricks: Always use a calibrated torque wrench. Clean threads before tightening. Consult manufacturer-specific guidelines when available.

Mastering metric bolt torque specifications is essential for anyone working with mechanical assemblies. From preventing stripped threads to ensuring the safety and reliability of critical components, a metric bolt torque chart is an invaluable tool. By understanding the importance of proper tightening techniques and utilizing the resources available, you can avoid costly repairs and ensure optimal performance. Invest in a good quality torque wrench, familiarize yourself with the appropriate charts, and make correct tightening a habit. Your projects will thank you for it.

Finding solace galloway funeral home obituary resources

Unlocking the power of stick figure art

Bud not buddy chapter 4 a deep dive into lefty lewis