Mastering VW Axle Nut Torque: Your Complete Guide

Ever wondered about that seemingly insignificant nut holding your Volkswagen's wheel assembly together? The VW axle nut, though small, plays a crucial role in your vehicle's safety and performance. Properly torquing this nut is paramount to maintaining correct wheel bearing preload, ensuring smooth operation, and preventing premature wear. This guide delves deep into the world of VW axle nut torque, providing you with the knowledge and practical advice you need to maintain your vehicle effectively.

Understanding VW axle nut torque specifications is essential for any VW owner or mechanic. Incorrect torque can lead to a range of problems, from wheel bearing failure and excessive play to rotor damage and even wheel detachment. Applying the correct torque ensures the wheel bearing is preloaded just enough to eliminate play without causing excessive friction or damage. This delicate balance is crucial for optimal performance, handling, and safety.

While the concept of tightening a nut seems straightforward, the specifics of VW axle nut torque can vary based on the model, year, and even the specific axle design. Therefore, relying on general guidelines or guesswork is highly discouraged. Always consult your vehicle's repair manual or a reputable online database for the precise torque specifications for your particular VW model. This information is vital for achieving optimal wheel bearing preload and preventing potential issues down the road.

The history of VW axle nut torque, much like the evolution of automotive engineering itself, has seen advancements in materials, designs, and tightening procedures. Early VW models may have employed simpler axle designs and torque specifications, whereas modern VWs often incorporate more complex systems requiring precise torque values and specialized tools. Understanding this historical context underscores the importance of referring to the correct documentation for your specific vehicle.

The importance of correct VW axle nut torque cannot be overstated. It directly impacts the longevity and performance of your wheel bearings, a critical component for smooth and safe driving. Proper torque also influences the overall handling and stability of your vehicle. Over-torquing can lead to premature bearing failure, while under-torquing can result in excessive play, noise, and potential wheel detachment. Achieving the correct torque is a crucial step in maintaining the integrity of your VW's suspension system.

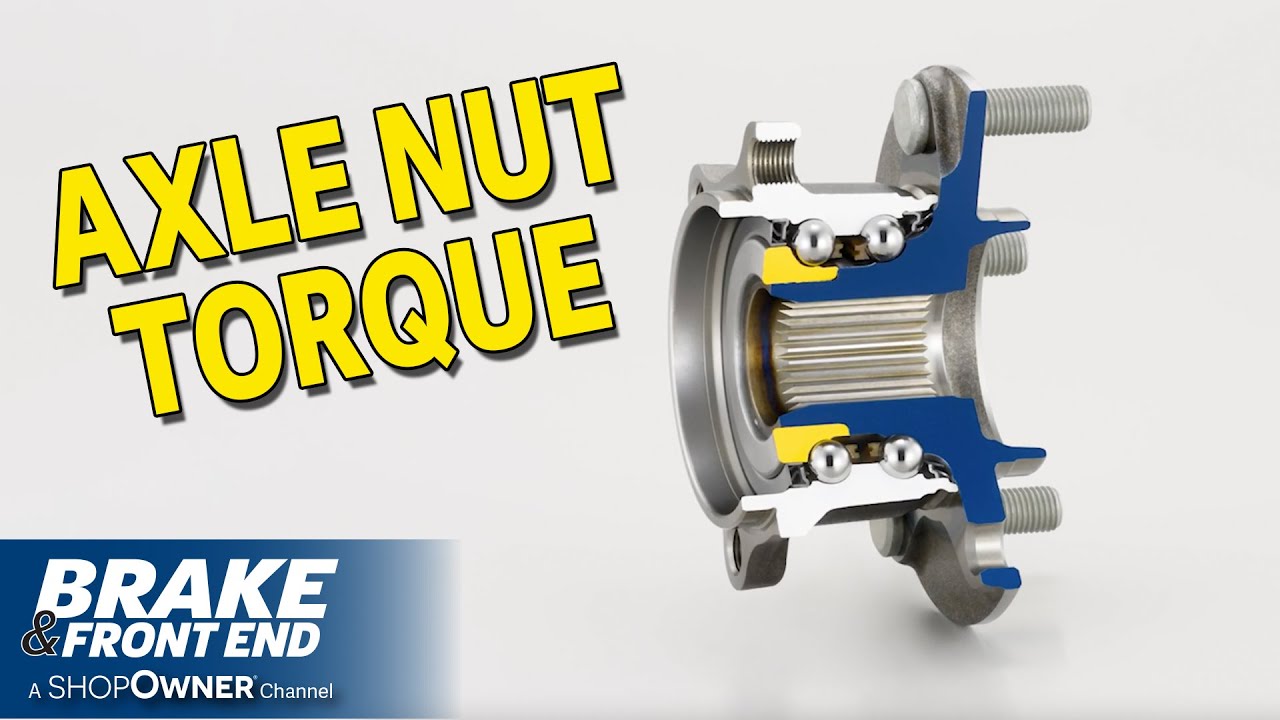

A VW axle nut, in simple terms, is a fastener that secures the drive axle or wheel hub to the vehicle's suspension. It plays a crucial role in maintaining the correct wheel bearing preload. For example, on a VW Golf, the axle nut torque specification might be 180 Nm + 90°. This means you tighten the nut to 180 Newton-meters and then further rotate it an additional 90 degrees. This specific procedure ensures the proper preload is achieved.

Benefits of proper VW axle nut torque include: Extended wheel bearing life, Improved handling and stability, Reduced risk of wheel detachment, Prevention of rotor damage.

Best Practices: Always consult your vehicle’s repair manual for the specific torque specification, Use a calibrated torque wrench for accurate tightening, Clean the axle threads and hub face before installation, Use a new axle nut whenever possible, Double-check the torque after driving a short distance.

Challenges and Solutions: Stripped axle nut threads: Use a thread chaser or replace the axle. Difficulty achieving the specified torque: Ensure the torque wrench is properly calibrated. Noise after tightening: Double-check the torque and inspect the wheel bearing for damage.

FAQ: What is the torque specification for my VW Golf? Consult your vehicle's repair manual. What type of torque wrench should I use? A calibrated click-type or beam-type torque wrench is recommended. Can I reuse an axle nut? It's best to use a new nut whenever possible. What happens if I over-torque the axle nut? You risk damaging the wheel bearing. What happens if I under-torque the axle nut? The wheel could become loose and detach.

Tips and Tricks: Mark the nut and axle with paint before tightening to visually confirm the 90-degree rotation. Use a breaker bar and socket for loosening stubborn axle nuts.

In conclusion, mastering VW axle nut torque is a fundamental aspect of VW maintenance. Understanding the importance of correct torque, consulting the proper documentation, and following best practices ensures the longevity of your wheel bearings, enhances vehicle handling, and most importantly, contributes significantly to your safety on the road. Don’t underestimate the power of this small but critical component. By taking the time to learn and apply the correct techniques, you’re investing in the long-term health and performance of your Volkswagen. Proper VW axle nut torque is not just a mechanical detail; it’s a cornerstone of safe and reliable driving. Remember to always prioritize safety and consult reliable resources for the specific torque specifications for your VW model. By doing so, you'll be taking a proactive step towards preventing potential issues and ensuring a smooth, enjoyable driving experience for years to come.

Keeping montclair clean your guide to trash and recycling

Finding your perfect fit understanding bike wheel sizes in the uk

Vacuum air conditioning without a pump cool innovation