Understanding Condensate Drain Systems

Imagine water droplets forming on a cold glass of iced tea on a humid day. This is condensation, and a similar process occurs in many appliances, like air conditioners and furnaces. These appliances produce condensation that needs to be managed effectively, which is where a condensate drain system comes into play. Understanding the workings of these systems is crucial for maintaining efficiency and preventing potential water damage.

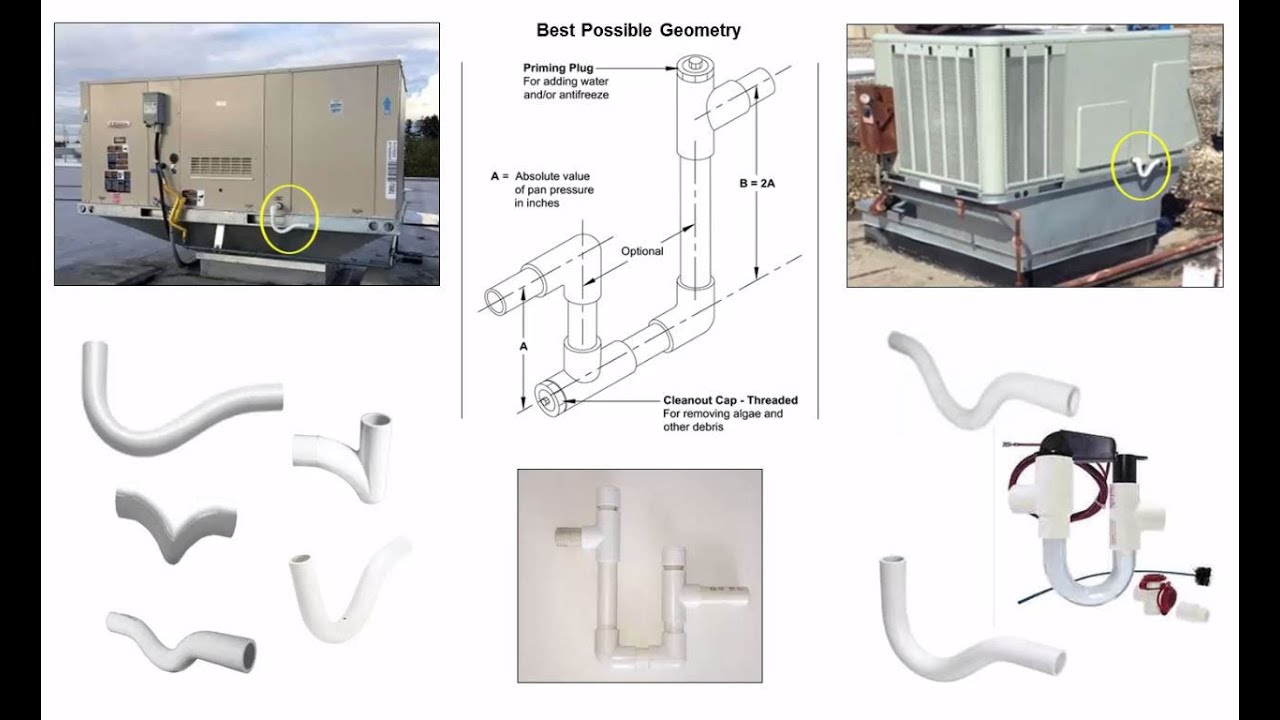

A condensate drain line illustration or schematic can help visualize the process. Essentially, it's a pathway for the collected condensation to be removed. These systems are vital for appliances and industrial processes that generate condensation. Without a proper drainage setup, this excess moisture can lead to problems like mold growth, equipment damage, and even structural issues in buildings.

Historically, managing condensate wasn't always a priority. Early heating and cooling systems often lacked dedicated drain lines, leading to various issues. As technology advanced, the importance of proper condensate removal became clear, leading to the development of more sophisticated systems. Today, condensate drain systems are integral to many appliances and industrial processes, ensuring their smooth and efficient operation.

One of the most common problems associated with a condensate drain layout is clogging. Dust, debris, and even algae can build up in the lines, obstructing the flow of water. This can lead to overflows and water damage. Regular maintenance, including cleaning the drain line, is crucial to prevent these issues. Understanding the components of a condensate drain system, as shown in a condensate drain system schematic, can help in troubleshooting and maintenance.

A typical condensate drain pipe diagram will show the pathway from the appliance that generates the condensation to the point of disposal. This path may include a drain pan, a P-trap to prevent sewer gases from entering the appliance, and the drain line itself. Some systems also include a pump to move the condensate vertically or over long distances. Familiarizing yourself with a condensate removal system diagram will help you understand its various components and how they work together.

One key benefit of a properly functioning condensate drain system is preventing water damage. By efficiently removing excess moisture, these systems protect the surrounding areas from mold growth and structural problems. Another advantage is improved air quality. By preventing stagnant water, these systems minimize the risk of mold and mildew, which can negatively impact indoor air quality. Finally, a well-maintained system contributes to the longevity and efficiency of the appliance it serves.

An effective action plan for maintaining a condensate drain system includes regular inspections and cleaning. Check the drain pan for any signs of debris or standing water. Flush the drain line with water or a mild cleaning solution to prevent clogs. Inspecting the condensate drain lines diagram can assist in identifying all components that require attention.

Advantages and Disadvantages of Condensate Drain Systems

| Advantages | Disadvantages |

|---|---|

| Prevents water damage | Potential for clogging |

| Improves air quality | Requires regular maintenance |

| Enhances appliance longevity | Can be complex in some applications |

Best practices include regular cleaning, proper installation following a condensate drain line design, and using appropriate materials. Ensure the drain line has a proper slope to facilitate gravity-driven drainage. Regularly inspect the system for leaks or signs of blockage. Understanding a condensate drain diagram helps in identifying potential problem areas.

Frequently asked questions about condensate drain systems often center around maintenance, troubleshooting clogs, and choosing the right type of system. Understanding the basics of a condensate drain pipe layout can help answer many of these questions.

In conclusion, condensate drain systems are essential components in many appliances and industrial processes. They play a crucial role in preventing water damage, maintaining air quality, and ensuring the longevity of equipment. Regular maintenance and a clear understanding of the system, aided by a condensate drain system diagram, are key to its effective operation. By prioritizing these aspects, you can ensure a dry, healthy, and efficiently functioning environment. Take the time to understand your system and implement best practices for its long-term health and performance. Investing in proper maintenance now can prevent costly repairs and headaches down the road.

Hajj savings made easy maybank2u registration

Unlock serenity exploring blue grey with asian paints

Finding sayre morning times obituaries