Unlocking Precision Control: Understanding Stepper Motor Schematics

Stepper motors, renowned for their precise positional control, are integral to various applications, from 3D printers and CNC machines to robotics and industrial automation. Understanding their schematic representation is crucial for anyone working with these powerful devices. This article will delve into the intricacies of stepper motor schematic symbols, exploring their significance, variations, and practical uses.

Imagine a world without precise, controlled movement in machines. Many of the automated processes we rely on wouldn't exist. Stepper motors, unlike regular DC motors, rotate in discrete steps, allowing for highly accurate positioning. The key to integrating these motors into circuits lies in understanding their schematic symbols, the visual language that dictates their connection and control.

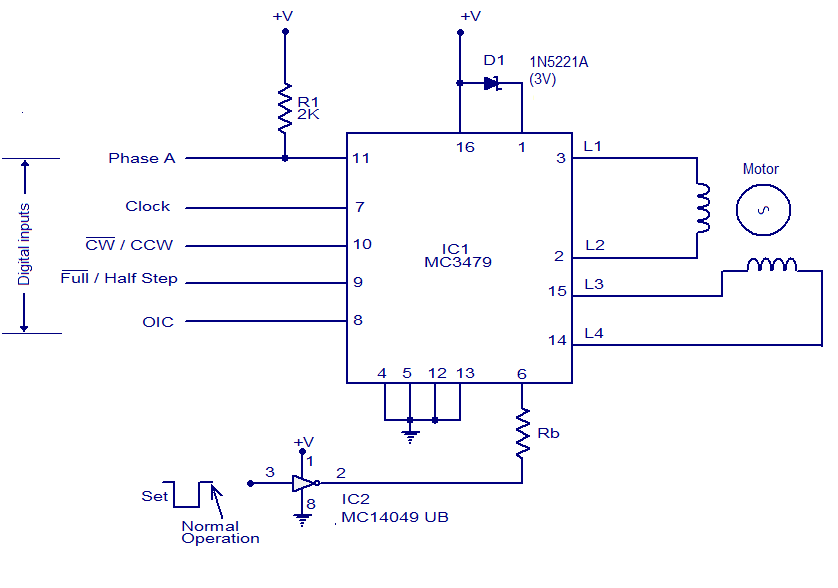

Stepper motor schematic symbols provide a simplified representation of the motor's internal windings and connections. They allow engineers and technicians to quickly grasp the motor's configuration and how it interacts with other circuit components. This standardized representation is vital for clear communication and efficient circuit design. Without a common visual language, designing and troubleshooting systems incorporating stepper motors would become significantly more complex.

While the core concept of a stepper motor schematic remains consistent, variations exist depending on the specific type of stepper motor, such as unipolar or bipolar, and the number of phases. These variations reflect the internal wiring configurations and dictate how the motor should be driven. Recognizing these subtle differences in the schematic is crucial for proper implementation and control.

Understanding the schematic goes beyond simply identifying the symbol. It involves recognizing how the connections relate to the motor's phases and how these phases are energized to achieve the desired rotational steps. This understanding empowers you to control the direction, speed, and holding torque of the stepper motor effectively.

The precise origin of the stepper motor schematic symbol is difficult to pinpoint, evolving alongside the development of electrical symbology. However, its importance is undeniable. Standardized symbols facilitate efficient communication among engineers and technicians worldwide. They minimize ambiguity and ensure that everyone involved in a project understands the circuit's functionality, regardless of language barriers.

A unipolar stepper motor schematic typically shows four connections, representing the common wire and the three phase wires. A bipolar stepper motor schematic, on the other hand, usually shows four connections, representing the two pairs of coils. These schematics are essential for wiring the motor correctly to the driver circuit.

Benefits of understanding stepper motor schematics include: 1) Efficient Troubleshooting: Quickly identify wiring errors and potential issues. 2) Accurate Circuit Design: Ensure proper integration with driver circuits and other components. 3) Effective Communication: Clearly convey design intent and functionality to others.

Best Practices: 1. Use the correct schematic symbol for your specific stepper motor type. 2. Clearly label all connections on the schematic. 3. Double-check your wiring against the schematic before powering the circuit. 4. Consider using simulation software to test your circuit design. 5. Consult datasheets for detailed specifications and wiring diagrams.

Advantages and Disadvantages of Stepper Motors

| Advantages | Disadvantages |

|---|---|

| Precise positioning | Can resonate at certain speeds |

| Open-loop control possible | Limited top speed compared to other motor types |

FAQ: 1. What is a stepper motor? 2. How does a stepper motor work? 3. What are the different types of stepper motors? 4. What is a stepper motor driver? 5. How do I choose the right stepper motor? 6. How do I control the speed of a stepper motor? 7. What are common troubleshooting issues with stepper motors? 8. What are some applications of stepper motors?

Tips and Tricks: Consult datasheets for specific stepper motor specifications. Use appropriate wiring techniques to minimize noise and interference.

In conclusion, understanding stepper motor schematics is paramount for anyone working with these versatile devices. From robotics to industrial automation, the precise control offered by stepper motors enables countless applications. Mastering the nuances of stepper motor schematics, including variations for different motor types, empowers engineers and technicians to design, implement, and troubleshoot stepper motor systems effectively. By following best practices and utilizing available resources, you can unlock the full potential of stepper motors and achieve precise motion control in your projects. This knowledge is essential for anyone looking to leverage the power and precision of stepper motors in their designs and projects. Take the time to study and understand these schematics – it's an investment that will pay off significantly in the long run as you confidently integrate stepper motors into your work. This deep understanding of stepper motor schematics is a key skill for any aspiring engineer or hobbyist working with motion control systems.

Unleash your inner artist easy animal drawings for beginners

Neck tattoos for men an inked exploration

Unlocking serenity the power of chantilly lace paint